When I first took the tank off the fuel filter was loose inside it and rattling about. I subsequently bought a new one which would not fit as the entry hole in the bottom of the tank was too small. I couldn't make out how the filter had got in there to start with, gave up and tried an external filter. By the way the bike came with a tiny in line cheapo plastic filter so someone else must have come to the same conclusion. Anyway today, for no particular reason, I offered up the new filter that came with the replacement fuel tap and noticed it had exactly the same dimensions as the sleeve inside the hole at the tank entry. Aha! Was the sleeve an old ferrule from the base of the loose filter? Only one way to find out. A few minutes with an oversize tap and hey presto out it came and the new one fits.. Great.

Saturday, 19 April 2014

Saturday, 12 April 2014

Wednesday, 9 April 2014

Sunday, 6 April 2014

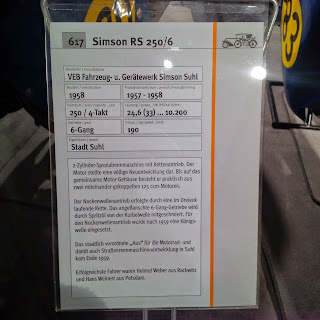

Simson factory Suhl

Signs of the times. 400 litres of oil per day seeped through the factory floor. The plating plant baths to the rear of the factory together with drums of fluid were filled in and tarmaced over to make a road when the factory closed. So much for environmental policy. The plant used so much electricity that appliances in the town of Suhl would not work. Simpson solved the problem by building their own on site generator. Whilst they were at it they built a steam generator so that the on site railway steam engines could be filled with steam rather than produce their own. With the isolation created by the Eastern bloc Simpson had no choice but to make any unavailable machinery and components themselves. They thus ended up by producing everything themselves on site. Little wonder then that this blinkered outlook caught them flatfooted when Communism failed on the 9th to 11th Nov 1989. From full production to shut down came in just 3 months. It was a disaster. Generations of families had walked to the plant from the houses overlooking it and known no other employment. 3000 jobs went with no other local work option.

Simson failed projects dept

80cc racer produced just in time for the class to be scrapped. Attempts to turn the disc valve, water cooled motor into a 125cc abandoned with arrival of Honda RS125.

BMW R35 1933 where it all began

This is where the basic AWO engine configuration came from. This design was also produced as an EMW, Eisenach Motor Werke, using a red and white propeller logo instead of the BMW blue and white.

Simson railway wagon

No half measures here ! Full size railway trucks ran on site then directly to station alongside site.

And the 2 stroke 2 seat 50cc Schwalbe, Swallow, scooter was made here

Dual seat, leading link forks, steel shrouded bodywork - the fastest 2 up 50cc scooter of its time, 30 mph two up !

Simson production was all on site

The site measured 2.5 km long by 500 metres wide. It was linked by the bridges between buildings. Here frames suspended on chains would be brought to the paint shop.

And don't forget the STASI - secret police

Buried in this hill was underground weapons manufacture. In front of it was STASI shooting range 300 metres long in use day and night.

Don't forget this was the DDR - East Germany run by Russia

Top left were the Party offices. Everything was on site so here were hairdressers, canteen general offices amongst others.

Tuesday, 1 April 2014

At last something that is wrong with Siegfried

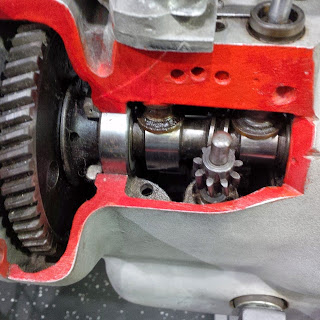

Finally found timing instructions for the Powerdynamo. When the piston is at Top Dead Centre, OT as per the stamping on the fly wheel lining up with the external lines stamped on the outside of the crankcase peep hole, the small red dot should be aligned to the left side of the sensor tip. Here it is 2cm to the right. Next need to get an M27x1.25 puller to take the dynamo off and position it correctly. Wolfgang is chasing down a rocker arm for my Simson factory visit on Thursday so we could be reinstalling quicker than I thought. Also if the timing is set too retarded then it may explain all the exhaust port soot and exhaust blueing as mixture is still being ignited with the exhaust valve still open. All I can do is set it up properly + reset carb needle to correct notch and see what we get.

Subscribe to:

Comments (Atom)